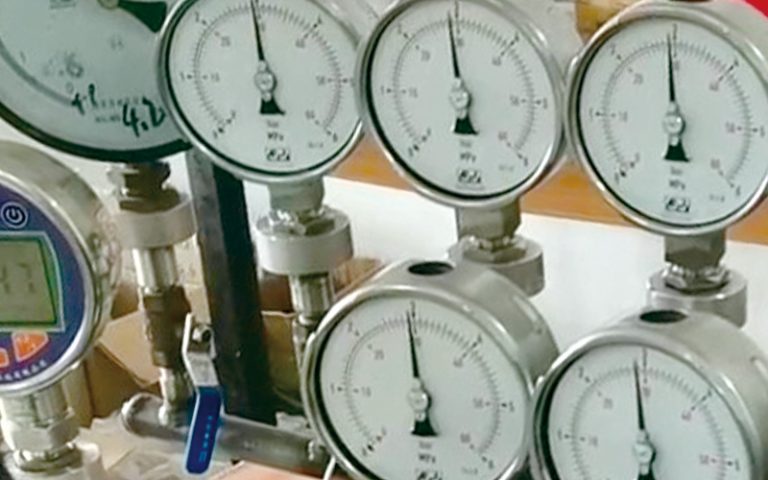

SJ Gauge has many years of professional experience in measuring pressure and temperature. In this article, we will share with you how to interpret pressure gauges. We will also provide guidance on how to handle damaged pressure gauges. Furthermore, we will discuss the six common causes of pressure gauge failure, allowing you to gain a comprehensive understanding through this article.

If you are interested in the topic of this article, please continue reading. Feel free to ask any questions or directly contact us. SJ Gauge is dedicated to providing you with the best answers and solutions.

1.What causes pressure gauges to fail?

There are many reasons that cause pressure gauges to fail, most of which involve improper operation and human error. As long as we understand pressure gauges well enough and use them carefully, we can avoid these situations. Through this article, we will cover common factors that lead to pressure gauge failure and how to avoid these problems. For more information on pressure gauge standards, refer to ASME B40.100-2013 and EN837-1.

2.The six main reasons for pressure equipment failure.

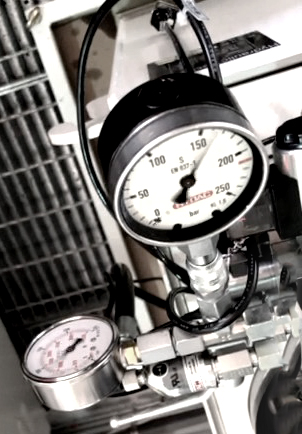

(a) Excessive vibration/pulsation

Reason:

The process equipment vibration will lead to pointer flutter and increase stress on the Bourdon tube. It might also cause damage to gears and other components in the long term.

Surges in process pressure can lead to pulsation, also causing pointer flutter and poor gauge readability. Degradation in integrity of gauge components may also occur.

Pressure spikes in the media often occur when turning on/off the valves frequently or when pressure sharply increases and drops, which might bend the pointer and break the stop pin.

Solution:

Using a PRA-CL Capillary for Pressure Gauge to mount the instrument further away from the source can decrease the vibration effectively.

Liquid-filled gauges can dampen the effect of pulsation. If the instruments are unsuitable to be liquid-filled, you can consider installing a PRA-SB Pressure Snubber to dampen the flow of process material.

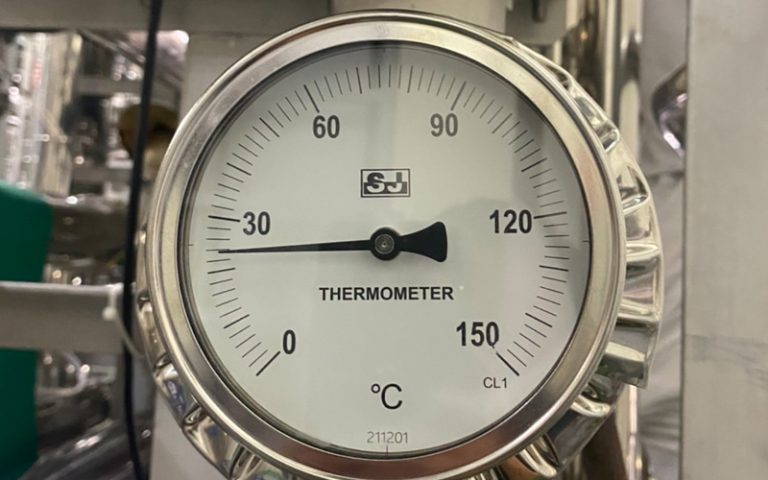

(b) Extreme high/low temperatures

Reason:

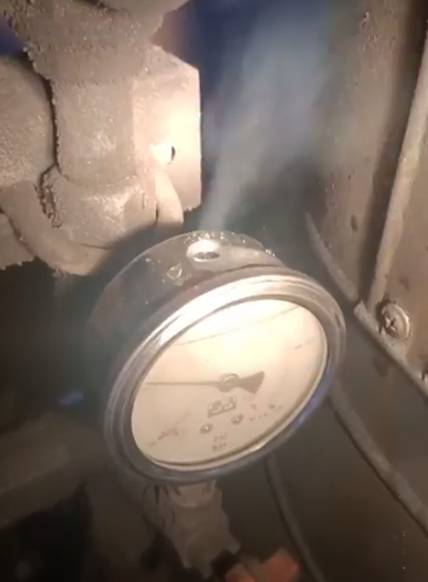

When the ambient temperature, or the temperature of the processed media, is higher than the tolerance of a pressure gauge, the dial, window and fill liquid are easily discolored. The gasket will harden and crack causing leakage from the rubber vent plug or other areas.

Bourdon tubes can rupture. These all put operators at risk of injury. When the temperatures are lower than the tolerance of the instruments, fill liquid will congeal and instruments will experience slow response time or create inaccurate readings.

Solution:

Air conditions, stoves and sprinklers can be mounted to maintain a stable ambient temperature.

A PRA-SP Stainless Steel Siphon Tube, heater and/or water-cooling system can be mounted to control the temperature of processed media. A PRA-C Cooling Element for Pressure Gauge is a good option if there is a space limit.

(c) Pressure spikes/overpressure

Reason:

There are many reasons for pressure spikes and overpressure, including machine malfunction, media freezing and rapid valve actuation,

all of which cause the pressure value beyond the full-scale range.

All these conditions will cause the Bourdon tube, dial and other components to deform or rupture, the pointer to bend, and result in accuracy degradation.

Solution:

When the instruments fail frequently and cause an unsteady pressure source, we recommend installing a Stainless Steel Overpressure Protector. This device can be set to shut off at the full-scale range to avoid damaging instruments.

When the pressure source is steady but the pressure value is still beyond the full-scale range, it’s better to choose a new gauge that accommodates the maximum operating value.

(d) Instrument clogging

Reason:

When the processed media is highly susceptible to crystallization (like salt water), is impure (like wastewater and sewage) or is too thick (like latex and asphalt), the Bourdon tube will stick and hinder operation.

Solution:

You can prevent clogging by integrating a filter or a diaphragm seal to block impurities. The diaphragm seal can isolate the media from the Bourdon tube while maintaining accuracy.

To learn more about the applications of diaphragm seals, see our article In what situation should a diaphragm seal be integrated to your pressure gauge.

(e) Instrument corrosion

Reason:

When measuring highly corrosive media (like hydrochloric acid, nitric acid, ammonia and sulfuric acid), Bourdon tubes may corrode and there may be leakage. It may also put operators at risk of injury.

Solution:

Integrate a diaphragm seal or choose a wetted part that is compatible with the corrosive media to extend the lifetime of pressure gauges and maintain the safety of operators.

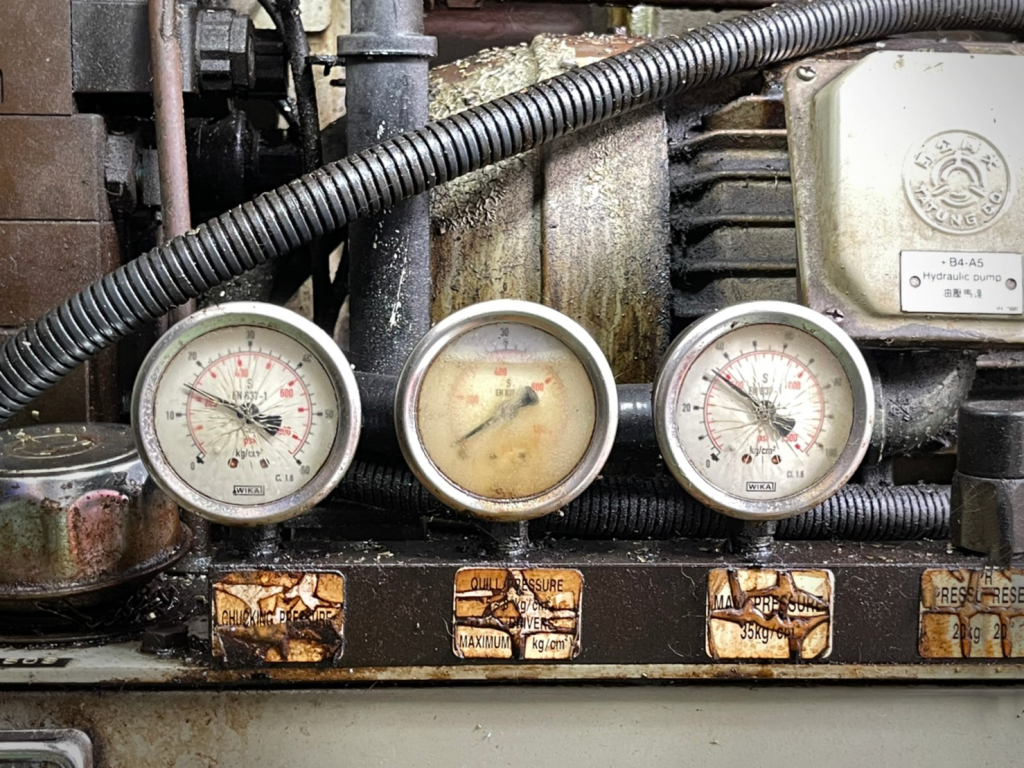

(f) Instrument abuse / mishandling

Reason:

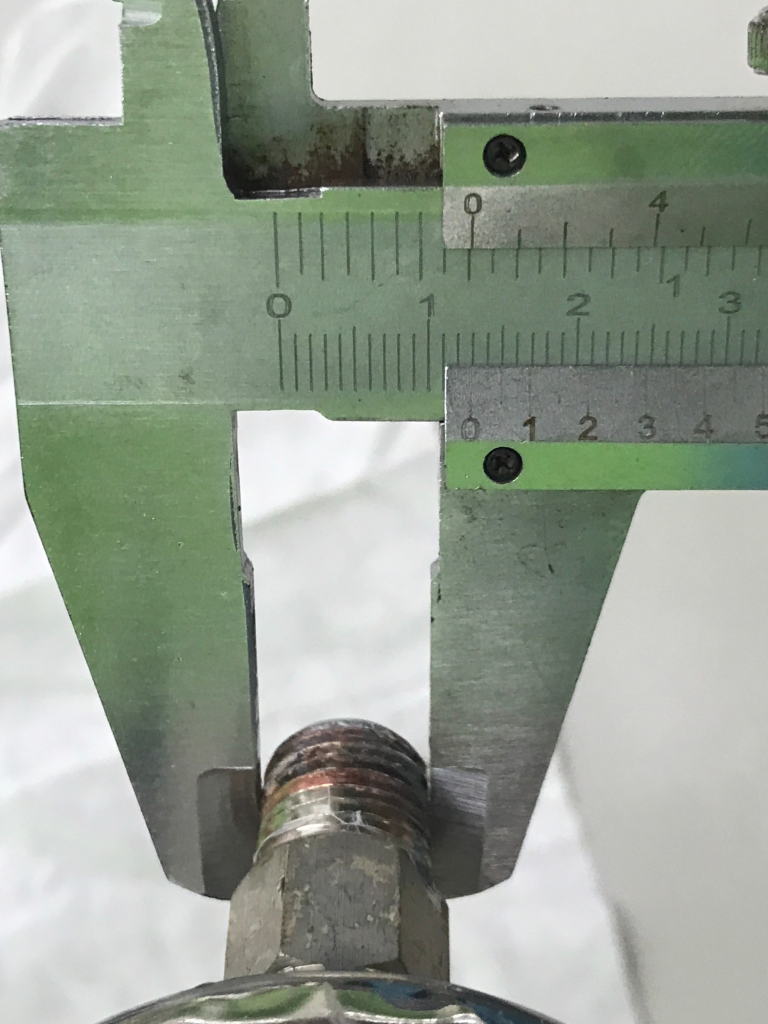

Incorrect installation and using threads of the wrong size can cause processed media to leak, instruments to lose accuracy and thread abrasion due to over-tightening.

Solution:

It’s necessary to choose the right size, type and shape of threads before installing instruments. Remember to use a wrench instead of holding the instrument case while installing and tightening instruments. Do not climb on a pressure gauge as a ladder after installing to avoid irreparable damage to the instruments.

Check Key Safety Points for Installing Pressure Gauges for more details.

3.Regular maintenance and servicing of pressure gauges

Understand industry standards of installation with our article on the introduction to and selection of threads. Inspecting the instruments routinely can ensure components work properly, extend the service life of instruments and maintain accuracy.