Valve Manifold for Pressure Instrument

- Divided into 2-valve manifolds, 3-valve manifolds, and 5-valve manifolds based on the applications

- Shut-off, pressure compensating, purge and vent valves for differential pressure measuring instruments

- Widely used in industries of petroleum, chemical, metallurgical, power, liquid, natural gas, and various conveying pipelines

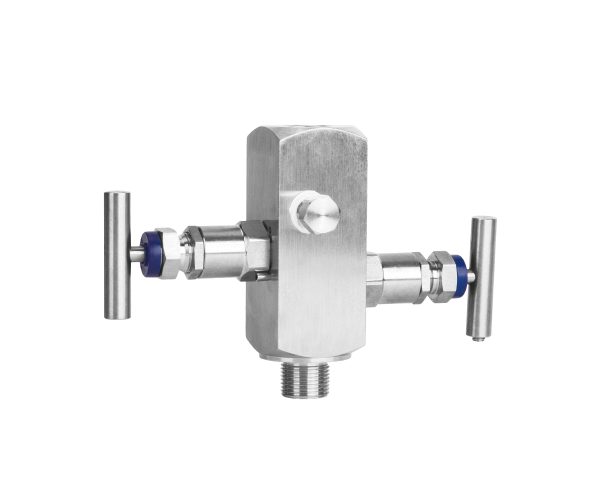

- Figure 1, 2: MSFZ20, 2-valve manifold

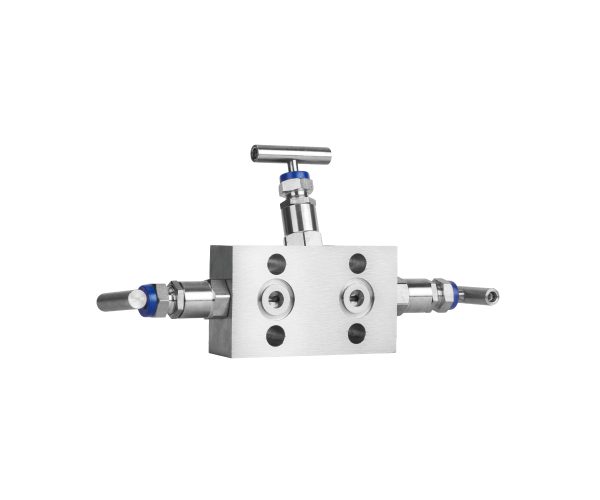

- Figure 3, 4: MSFZ30, 3-valve manifold

- Figure 5, 6: MSFZ50, 5-valve manifold

- アフターサービス / カスタマイズ可能

- 高品質・1年保証

- 画像はイメージです。実際の製品はお客様のカスタム仕様に基づきます。.

仕様

| Safety shotpin | Adopting stainless steel pin to prevent the valve seat out off the valve body due to vibration |

|---|---|

| Valve body design | Integral structure, firm and reliable |

| Valve seat seal | Stainless steel seal, safe and reliable |

| Valve spool | High-performance duplex stainless steel and spherical positioning function to improve sealing performance and service life of the valve |

| Lubricating grease | Imported grease used between the sealing gasket and adjusting screw to reduce friction and improve sealing performance |

| Material | 304 SS, 316 SS, Monel, Hastelloy C |

| Marked cover | Green, red, and blue marks for the pressure-leading valve, balance valve, and draining valve respectively |

| Stuffing box filler | PTFE |

| Working pressure | 32MPa, 42MPa |

| Working temperature | ≦150℃ |

| Ambient temperature | -30℃ ... +93℃ |

| Communication | RS485 Modbus RTU mode |

| Baud rate | 19200/9600/4800/2400 bps |

| Tempering temperature | 100 ppm/℃ (0℃ ... 60℃) |

| Ambient temperature& humidity | 0℃ ... 60℃/20% ... 90% RH (non-condensing) |