Are your pressure gauges often failing, even after they were replaced?

The problem may be related to the media (pressure source). Through this article, SJ Gauge will help you identify if your pressure gauge needs the addition of a diaphragm seal.

1. When the media crystallizes easily, contains impurities or is too thick:

During measurement, the media flows directly into the measuring system (Bourdon tubes, spiral tubes, bellows, etc.). To avoid clogging, a diaphragm seal should be integrated to isolate the pressure source. For example: the food and pharmaceutical industries often use sanitary diaphragm pressure gauges to measure pressure. This type of pressure seal can not only isolate the measurement media, but also be more easily cleaned and replaced. Common pressure sources that crystallize easily are salt water, pressure sources containing impurities, wastewater and sewage, and overly thick pressure sources such as latex and asphalt.

2. When the media is strongly acidic or corrosive:

Although measuring systems with stainless steel have weak acid and alkali resistance, a diaphragm seal is better suited for use for media with stronger alkali or corrosive properties. This prevents the media from directly flowing into the tube and causing corrosion or rupture. Examples of these media include: hydrochloric acid, nitric acid, ammonia and sulfuric acid. A lining and coating will also help prolong the service life of the gauge. Common diaphragm seal materials are: stainless steel, PTFE (Teflon), tantalum, and Hastelloy.

Check a corrosion resistance table of metal, plastic and PP to see the corrosion resistance of different materials for different chemicals.

But how do diaphragm seals work with pressure gauges?

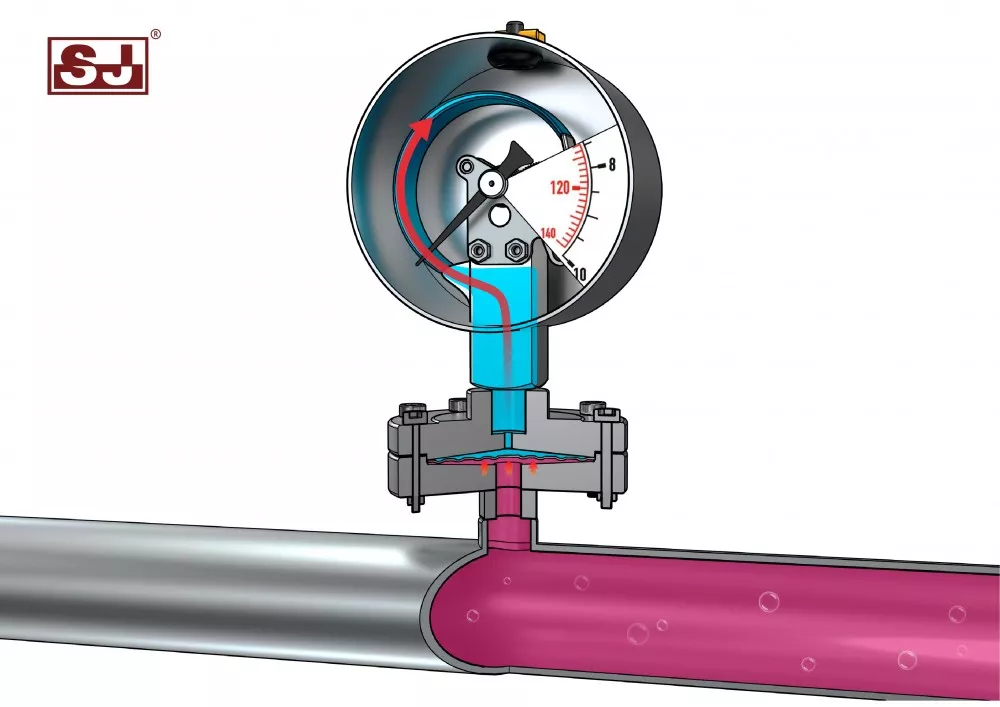

Without a diaphragm seal, the media will flow directly into the measuring system of a mechanical pressure gauge and drive the pointer to rotate. To learn more about the inner workings of pressure gauges, check out our article: What are the internal structures of mechanical pressure gauges.

Integrating a diaphragm seal to a pressure gauge adds a barrier under the connection thread. The gauge is then filled with a less harmful liquid (blue in the picture below), which receives pressure from the media (purple in the picture below) through the diaphragm and drives the pointer.

The application of diaphragm seal pressure gauges:

Common industries that use diaphragm seals: petrochemical, medical, pharmaceutical, and food. They are also used in many power plants.

The connection design of diaphragm seal pressure gauges:

There are three main types of diaphragm seals: threaded, flange, and sanitary. Selection of each type depends on several factors such as industry, pressure media, space restrictions, and connection location. The pictures below can give you some ideas. If you think you may need a diaphragm seal, be sure to ask for more information.

|

Threaded diaphragm seals |

|

|

Hopefully, this article has helped you determine if a diaphragm seal pressure gauge might be the solution to your problem. If you are still unsure or need further assistance, feel free to contact us. We’re happy to help.