Taiwan shipyard needed custom temp gauges with special angles made of stainless steel. Look at how SJ Gauge uses its existing models to solve the problem...

#01Client background

Since the opening of ports to merchants and trade during the Qing Dynasty, Taiwan has been regarded as the main hub for international shipping. As a leading domestic shipyard, it primarily manufactures merchant and container ships. They also build special ships, such as engineering ships, tugboats, and dredgers.

#02Challenge

Although the masterful technique is a prerequisite to building sturdy and durable ships, regular maintenance is also an important key that can't be ignored to prolong the life of ships.

During a routine inspection, the operator found an aluminum thermometer, which was installed on the transformer, sustained heavy damage from sun and water. The dial was also too light to read.

To replace the damaged thermometer, the shipyard contacted the original manufacturer but found that this type of thermometer had already been discontinued. They needed another solution.

#03Client demand

Because the required quantity was low, few manufacturers were willing to produce the highly customized order.

An internet search led them to SJ Gauge, which provides flexible customization.

#04Solutions and client feedback

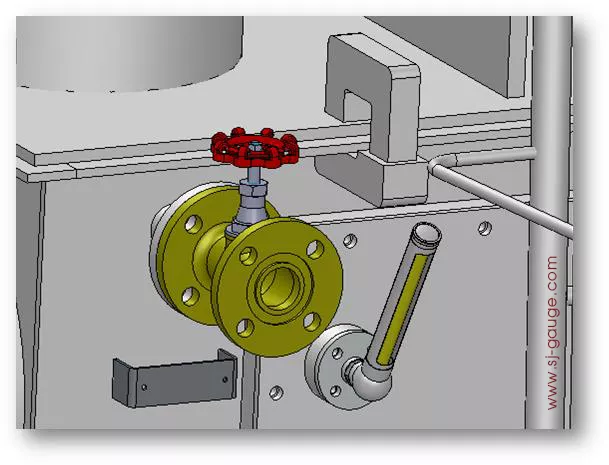

After discussing the project details, Our SJ Gauge team took our original DET Glass Tube Thermometer with Metal Housing as a starting point. We changed the case to stainless steel to endure the harsh elements while customizing the buried angle to 135 degrees to prevent reflection.

In a short period, the engineering ships could resume operations. As a bonus, they save the cost of replacing the entire transformer just because of a broken thermometer.