What Are the Internal Structures of Different Mechanical Pressure Gauges?

When measuring pressure, different pressure gauges can be selected according to different measuring methods, environments and pressure sources. SJ Gauge let you through this article, you will have a deeper understanding of the inner workings of mechanical pressure gauges.

1. Bourdon Tube

Let's start with the key component of Bourdon tube (also known as spring tube) gauges. They can be used to measure both liquid and gas. There are three kinds: C-type, helical type, and spiral type.

C-type Bourdon Tube:

C-type Bourdon tubes are made of a hollow, thin-walled, bent tube. Commonly made of copper or stainless steel, and used for between 0.6 and 70 kgf/cm² of pressure, they are the most prevalent type of mechanical pressure gauges. Fix the open end to the base for connecting to the pressure source and connect the sealing end to the link. When the pressure occurs, the bent Bourdon tube will produce a corresponding displacement due to the different pressure given, and the pointer will rotate.

Helical Bourdon Tube:

The multi-bending characteristics of the helical Bourdon tube help it dispers pressure easily. Compared to a C-type, a helical type can withstand higher pressure. It is often used for high pressures ranging from 70~ 1000 kgf/cm². The more the measured pressure value is, the more tube coils are required. Commonly used in the petrochemical industry, power stations and environmental engineering.

Spiral Bourdon tube:

Spiral Bourdon tubes are curved in concentric circles. The end of the tube is directly connected to the pointer, without using gears or links. Its simple structure is often used in pressure gauges with small dials, such as diving oxygen cylinders and fire extinguishers.

2. Diaphragm

Next, let's take a look at some diaphragm gauges. There are three types: link diaphragm, capsule, and gearless diaphragm gauges.

Link diaphragm:

The link diaphragm operates without any system fill fluid, which is safety for sterile pressure measurement. Common diaphragm materials are stainless steel, Teflon (PTFE), Hastelloy (Hastelloy) or ceramic. Pressure can be measured through the wavy diaphragm directly, and then the pressure will be transmitted through the link to the gear and pointer. A lining or coating can be applied to extend the service life. Link diaphragm pressure gauges can be used to measure aggressive medium, they're commonly used in the compressor or gas industry.

Gearless diaphragm:

Gearless diaphragm measures the pressure directly through the contraction and expansion of the diaphragm to squeeze the pointer rotation. This type of gauge doesn't need to be liquid filled to avoid internal shock (measuring media pressure instability) and external shock (vibration generated during the operation of the equipment) from affecting the observation or causing damage to the gear. Gearless diaphragm pressure gauges can also resist high collision. The disadvantage is its poor precision. It is commonly used in air compressors or as tire pressure gauges.

Capsule:

Two diaphragms are welded along and sealed to form a capsule. When pressure from the media changes, the capsule will expand (positive pressure) or shrink (negative pressure) according to the pressure. This directly affects the gear and link, which drives the pointer. Common materials used are copper and stainless steel. Capsule pressure gauges are often used as micro pressure gauges in the gas industry, petrochemical industry or medical industry.

3. Others

There are other types of pressure gauges that don't fall into the Bourdon tube or diaphragm category, but they are no less useful for industries that need them. Let's look at two kinds: bellows and piston.

Bellows:

Bellows are a kind of hollow tube with an annular corrugated pattern. When the pressure charges, the bellows will extend along the direction of the tube, driving the gear and link to rotate the pointer. In addition to being a general pressure gauge, it is also often used as a differential pressure gauge. The principle is to connect a bellow on the both sides of the pressure media separately. Through the difference in pressure between the two sides, the pointer will rotate. These gauges are usually used to measure pressure differences ranging from 0 ~ 25 kgf / cm². The maximum static pressure is 150 kgf / cm². Common materials of bellows are stainless steel, brass and bronze. You will usually find these gauges in air conditioning systems, filtration systems and exhaust pipe detection systems.

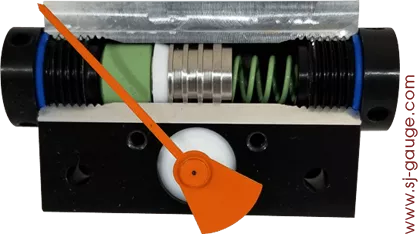

Piston:

Piston pressure gauges are mainly used as differential pressure gauges. Two different pressures are connected to the different sides of the gauge. The higher pressure will push against the lower pressure, causing the piston to push the remaining pressure to the lower pressure. This squeezes the spring and rotates the pointer. Piston gauges are mainly used for pump monitoring and pipeline systems.