In this case study, our client is a leading company in the Taiwanese petrochemical industry. In the aftermath of World War II, the petrochemical sector in Taiwan experienced rapid growth during the 1950s, marking the golden era of economic development. Taiwan's petrochemical industry primarily focused on downstream demands, which, in turn, attracted upstream investment, shaping the supply chain of Taiwan's petrochemical sector.

In the following success story, SJ Gauge will share details of how we have, through optimal solutions, shared our expertise and support to help our client achieve their needs and goals.

#01Client background

The client we are serving in this case belongs to the Petrochemical Industry, which refers to the industrial sector that primarily utilizes petroleum or natural gas as raw materials to produce various chemicals such as synthetic plastics, rubber, synthetic fibers, and various chemical products.

#02Challenge

The petrochemical industry often needs to measure the liquid level in storage tanks. In this case, the client intends to measure a medium primarily composed of acrylic, combined with water (as a solvent), emulsifiers, and initiators. This medium results in a milky-white polymer latex obtained through an emulsion polymerization process.

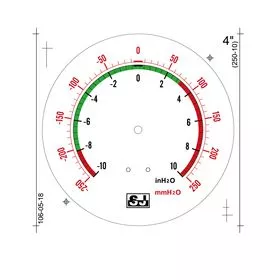

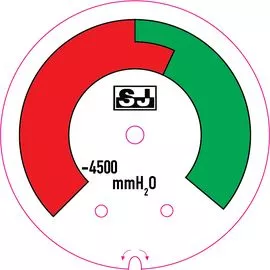

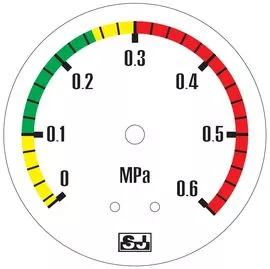

To properly manage and maintain consistent standards, it is very important to our clients that instrument dials match those they already have. This ensures that the observing personnel can continue their usual practices without disruption.

#03Client needs

2. The client deals with a complex measuring medium and requires outdoor installation of the instrument.

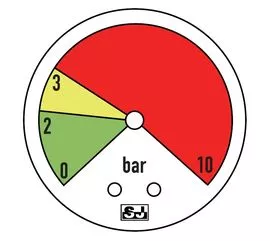

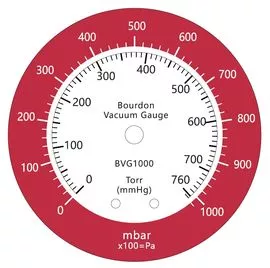

3. Customization of the dial, including essential information, part numbers, warning colors, and unit markings.

#04Solutions

1. Pressure gauges can also be used for liquid level measurement. SJ Gauge installed them at the bottom of the tanks. The principle is that the pressure of the medium at the bottom is directly proportional to the tank's height, allowing the liquid level to be determined by reading the pressure gauge.

2. To survive a viscous and corrosive medium in an outdoor environment, exposed to wind and sunlight, we crafted custom pressure gauges. A stainless steel case and wetted parts gave the gauge enhanced durability and resistance. This ensured proper operations for our client.

3. SJ Gauge printed customized dials based on the unique requirements of our client.

Why choose SJ Gauge?

When is a custom pressure gauge dial needed? What are the benefits of custom dials?

Here are some situations where SJ Gauge's expertise in serving various industries has highlighted the need for custom dials:

- OEM manufacturers wish to purchase instruments for their production lines that showcase their company name.

- Instrument suppliers want to promote their company name, logo, website, and contact information, such as phone numbers, on pressure gauges.

- Factories need to procure replacement parts for instruments and add their contact details to the dial.

- For safety reasons, such as identifying hazardous areas, or zones, or when maintenance is required, clients want to add color zones on the dial.

- Manufacturers require a change in the color of the scale on the dial.

- Clients' applications require specialized scale markings on the dial to represent multiple units of measurement.

- Clients need unique or non-standard units of measurement to convert pressure values into flow rates, liquid levels, and more.

SJ Gauge also offers comprehensive after-sales services, including product warranties and maintenance checks, ensuring that clients receive prompt support in the future.

Credits and References: Chang Chun Group

Old Photos of pressure gauge provided by SJ Gauge client

Old Photos of pressure gauge provided by SJ Gauge client