-

Differential pressure is essentially a way to “see the real condition of equipment.”

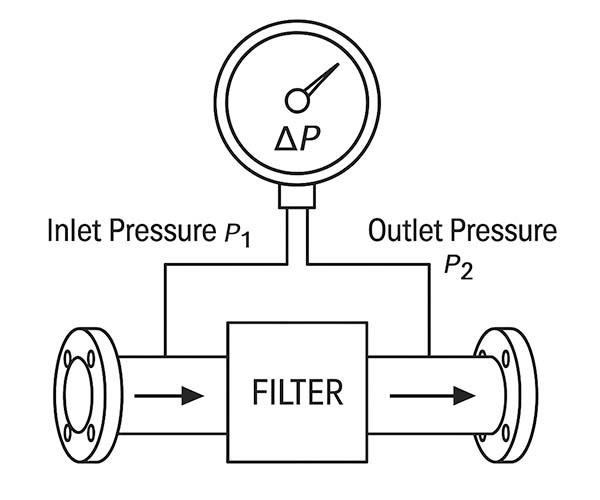

In many industrial applications—whether in water treatment, chemical processing, cooling water systems, or food production lines—the most common instrument installed next to filters is the differential pressure gauge. The reason is simple: differential pressure reveals when a system is starting to become inefficient—before a failure actually occurs.

Differential Pressure (DP) refers to the pressure difference between two points, such as the inlet and outlet of a filter. The inlet pressure is higher, the outlet pressure is lower, and the difference between them is the differential pressure. As resistance increases, the differential pressure rises. The higher the differential pressure, the greater the resistance—and the closer the filter is to becoming clogged.

Compared with a standard pressure gauge that only shows a single-point pressure, differential pressure directly reflects the “health condition” of the entire system, allowing operators to instantly judge whether maintenance is needed.Why Filters Must Use Differential Pressure

A filter’s condition cannot be judged by appearance alone. Whether the filter element is clean or clogged, and whether flow resistance has increased, is usually not discovered until flow rate drops significantly. Differential pressure, however, provides a powerful early warning capability.

For example, a new filter element may have a differential pressure of only about 0.1 bar. After operating for some time, as impurities accumulate and resistance increases, the differential pressure will gradually rise to 0.3, 0.4, or even 0.5 bar. At this stage, the system is still running and flow has not yet dropped sharply—but the differential pressure is already signaling:

“It’s time to replace the filter.”

This is why many users initially underestimate the importance of differential pressure, but after installation, it quickly becomes one of the most relied-upon daily inspection tools.

-

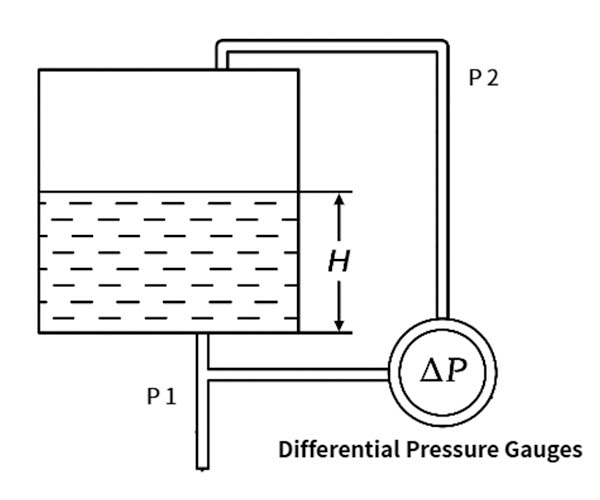

Differential Pressure for Level Measurement

In addition to filtration, differential pressure is also very commonly used for liquid level measurement. Liquid level is proportional to the hydrostatic pressure at the bottom of a tank, and in closed tanks, the gas pressure at the top must also be deducted; therefore, differential pressure measurement is ideal for converting the pressure difference between the bottom and the top into liquid level height. This method is especially suitable for high-temperature liquids, corrosive chemicals, foaming liquids, and sealed vessels. Because differential pressure transmitters or gauges do not need to be inserted into the liquid and only require two pressure tapping points to operate, they are both safe and stable. Many customers who replaced floats or ultrasonic sensors with differential pressure most often say, “We finally no longer need to constantly adjust the system or worry about foam interference.”

The True Value of Differential Pressure

Differential pressure may appear simple, but it provides early warning capability. Before a filter becomes completely clogged, the differential pressure begins to rise gradually; before a pump overheats, differential pressure already shows the decline in flow; before the liquid level reaches overflow, the pressure difference also reflects the change in advance. Therefore, differential pressure is one of the most economical, direct, and practical methods of equipment protection. Many sites even list differential pressure values directly in their maintenance SOPs, such as “replace the filter when the differential pressure reaches 0.4 bar,” turning maintenance into a predictable process rather than something left to chance. This approach not only reduces equipment failure rates but also saves unnecessary wear and losses.

-

Advantages of SJ Gauge Differential Pressure Gauges

Because each application differs in terms of medium, pressure, and installation method, market demand for differential pressure is highly diverse. SJ Gauge differential pressure gauges can be customized for different situations, including scale range, dial color, logo, materials such as stainless steel, PTFE, and diaphragm designs, as well as connection orientation and mounting positions. This allows customers to obtain the most suitable configuration for RO water treatment, chemical acid tanks, electroplating systems, or cooling water filtration. At the same time, our differential pressure gauges offer high durability, solid construction, resistance to drift, and significantly shorter lead times than international brands, which is especially helpful for factories that need rapid implementation.

-

Conclusion

In conclusion, if your equipment includes filters or liquid level measurement, you will almost certainly need differential pressure. Differential pressure is not a complicated technology, but a tool that helps you discover problems earlier, avoid downtime, protect equipment, and make production lines run more smoothly. For filters, it is the most accurate indicator of blockage; for tanks, it is the most stable method of liquid level monitoring; and for operating plants, it serves as a constant on-site guardian. If you would like to select a suitable differential pressure gauge, customize the scale or materials, or determine what differential pressure value means “it’s time to change the filter” for your system, I can help you organize a complete selection recommendation.