How to Choose the Right Pressure Transmitter for a Specific Application?

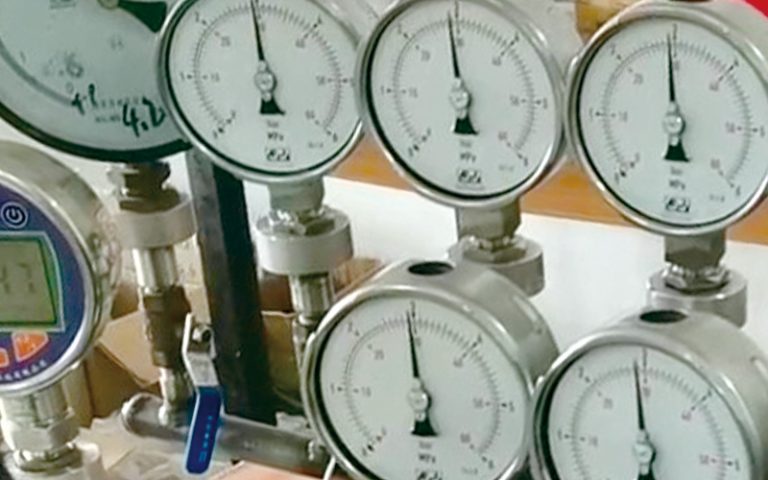

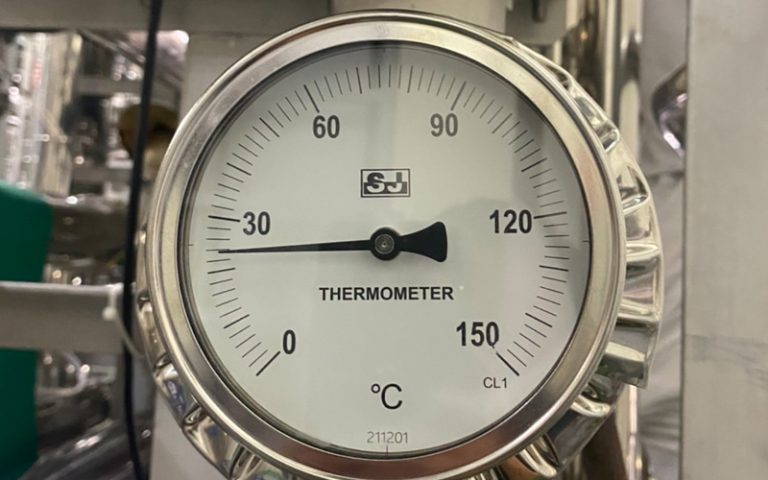

A pressure transmitter is a widely used industrial sensing device designed to measure the pressure of gases, liquids, or steam and convert it into a standard electrical signal (e.g., 4-20mA, 0-10V).

However, different working environments impose distinct requirements on pressure transmitters. Explosion-proof and general pressure transmitters serve as two major categories, each tailored to specific application needs. This report comprehensively analyzes their differences in design philosophy, structural characteristics, working principles, application scenarios, certification standards, cost, and maintenance, providing readers with an in-depth technical reference.

Explosion-Proof Pressure Transmitters vs. General Pressure Transmitters

| Comparison Item | Explosion-Proof Pressure Transmitter | General Pressure Transmitter |

|---|---|---|

| Design Philosophy | Designed for explosive environments to prevent ignition from electrical sparks or high temperatures, prioritizing safety. | Focuses on pressure measurement accuracy and cost-effectiveness without considering explosion risks. |

| Material Structure | High-strength housing (e.g., 316L stainless steel, aluminum alloy), high sealing performance (IP66-IP68), and resistance to internal explosion pressure. | Common materials such as plastic or standard metals, with moderate sealing performance (IP54-IP65). |

| Working Principle | Pressure measurement + explosion-proof technology (e.g., flameproof Ex d, intrinsic safety Ex i), limiting energy or sparks. | Measures pressure and outputs a standard electrical signal (e.g., 4-20mA) without explosion-proof design. |

| Certification Standards | Must comply with international explosion-proof standards (e.g., ATEX, IECEx), with zoning classifications (Zone 0/1/2) and gas group categories (IIB/IIC). | Meets basic industrial standards (e.g., CE, UL) without explosion-proof certification requirements. |

| Application Scenarious | High-risk environments: oil & gas pipelines, chemical reactors, coal mines (gas monitoring), pharmaceuticals (flammable solvents). | General environments: water treatment, HVAC, food processing, mechanical manufacturing (hydraulic systems). |

1. Design Philosophy and Safety Considerations

1.1 Purpose of Explosion-Proof Pressure Transmitters

Explosion-proof pressure transmitters are specifically developed for hazardous environments where flammable gases (e.g., methane, hydrogen), vapors, or combustible dusts are present. Their primary objective is to operate safely without triggering explosions.

For example, in petroleum refineries or coal mine ventilation systems, even a minor electrical spark or excessive temperature can lead to catastrophic consequences. Hence, explosion-proof pressure transmitters must not only fulfill pressure measurement requirements but also prevent explosion propagation.

Explosion-proof designs typically follow two principles:

Flameproof (Explosion-proof, Ex d) – Encloses potential ignition sources within a robust housing, preventing explosions from affecting the external environment.

Intrinsic Safety (Ex i) – Limits electrical current and voltage to prevent energy levels from reaching ignition thresholds, even under fault conditions.

1.2 Purpose of General Pressure Transmitters

In contrast, general pressure transmitters focus on cost efficiency and are used in non-explosive environments such as water treatment plants, air conditioning systems, or mechanical workshops. These devices are designed for standard industrial applications without explosion-proof considerations.

1.3 Impact of Safety Differences

Due to their distinct design philosophies, explosion-proof pressure transmitters require far stricter safety measures than general models. For instance, every circuit component in an explosion-proof model (Ex d) undergoes rigorous testing to ensure it cannot act as an ignition source. In contrast, general pressure transmitters prioritize mechanical durability (e.g., pressure and corrosion resistance) rather than explosion protection.

2. Structural and Material Differences

2.1 Structural Features of Explosion-Proof Pressure Transmitters

Explosion-proof pressure transmitters are built with high-strength, highly sealed structures. Their housings are typically made from stainless steel (e.g., 316L) or aluminum alloy, specifically engineered to withstand internal explosions. Some models (e.g., SJ MS Series, Emerson 3051 Series) feature flameproof enclosures that contain any potential ignition.

The sealing level of these devices generally reaches IP65 to IP68, effectively preventing external gases or dust from infiltrating. Additionally, explosion-proof models use specialized connection components such as explosion-proof cable glands to maintain airtightness.

Internally, these transmitters incorporate features like isolation diaphragms, anti-static coatings, and energy-limiting modules to prevent dangerous sparks or heat in high-pressure or fault conditions.

(Learn More: Advanced Transmitter Series)

2.2 Structural Features of General Pressure Transmitters

General pressure transmitters have more flexible material choices, including plastic (e.g., polycarbonate) or standard metal casings, with lower strength and sealing requirements. For instance, plastic housings suffice for low-pressure applications, while standard stainless steel housings are used for moderate pressure environments. These devices usually meet IP54 to IP65 standards for dust and water resistance but lack explosion-proof capabilities.

2.3 Impact of Material and Structure on Performance

Explosion-proof pressure transmitters offer enhanced durability in extreme environments (e.g., high temperatures, humidity, or corrosive gases) but come at a higher cost. In contrast, general pressure transmitters feature lightweight designs that are easier to install and replace but may have lower durability in harsh conditions.

(Learn More: Corrosion Resistance Chart for Pressure Gauge with Metal Connectors)

3. Technical Differences in Working Principle

3.1 Working Principle of Explosion-Proof Pressure Transmitters

Explosion-proof transmitters operate similarly to general models by converting pressure into electrical signals. However, their key difference lies in integrating explosion-proof technologies:

Flameproof (Ex d) – The housing withstands internal explosion pressure and dissipates heat through special channels (e.g., flame arrestors).

Intrinsic Safety (Ex i) – Electrical circuits incorporate components like Zener diodes or current-limiting resistors to restrict energy levels below 1W, ensuring non-ignition.

3.2 Working Principle of General Pressure Transmitters

General pressure transmitters simply measure pressure and convert it into an electrical signal. For instance, piezoresistive transmitters use the piezoresistive effect of silicon crystals to detect pressure changes, converting resistance variations into voltage signals through a Wheatstone bridge. These devices do not require energy-limiting measures or spark protection.

3.3 Complexity of Technical Implementation

Explosion-proof pressure transmitters require additional technologies, such as safety barriers (Ex i) or rigorous flameproof testing (Ex d), making their design and production more complex. General pressure transmitters, on the other hand, follow a standardized manufacturing process with fewer safety constraints.

4. Certification Standards

4.1 Explosion-Proof Pressure Transmitter Certifications

Explosion-proof pressure transmitters must meet international or regional safety standards, including:

ATEX (Europe) – Defines hazardous area classifications and gas types.

IECEx (Global) – A worldwide explosion-proof certification system.

FM/UL (USA) – Certifications for North American markets.

These standards specify safety ratings (e.g., Ex d IIC T4) to ensure safe operation in hazardous conditions.

4.2 General Pressure Transmitter Standards

General pressure transmitters must comply with basic industrial regulations such as CE (European Conformity) and ISO 9001 (Quality Management), which focus on performance rather than explosion safety.

5. Application Scenarios

5.1 Where Explosion-Proof Pressure Transmitters Are Used

Industries that require explosion-proof transmitters include:

Oil & Gas – Wellhead and pipeline pressure monitoring.

Chemical Plants – Reactor and storage tank pressure measurement.

Mining – Gas pressure monitoring to prevent explosions.

Pharmaceuticals – Used in volatile solvent environments.

5.2 Where General Pressure Transmitters Are Used

Common applications include:

Water Treatment – Monitoring pump and pipeline pressure.

HVAC Systems – Measuring air or duct pressure.

Food Processing – Controlling pressure in pressing or filling operations.

Mechanical Manufacturing – Hydraulic and pneumatic system monitoring.

6. Conclusion

Explosion-proof pressure transmitters prioritize safety in hazardous environments, incorporating rugged housings, specialized circuitry, and strict certifications. General models focus on cost efficiency and measurement accuracy for standard industrial applications.

Selecting the right transmitter depends on environmental risk: if flammable gases or dust are present, an explosion-proof model is required. Otherwise, a general model is the more economical choice.