Disclaimer:

The information provided in this article is intended for general reference only. Users should ultimately make product selections for their applications based on their judgment of the materials, chemical substances, and corrosion factors involved. This article does not provide any form of warranty, expressed or implied.In no event shall SJ Gauge, its distributors, and suppliers be liable for any damages arising from the use or inability to use this article, including but not limited to consequential damages, personal injury/negligence resulting in death, loss of profits, or business interruption. Such damages are disclaimed, whether advised of the possibility of such damages or not.

The careless use of this article may lead to accidents that endanger life and property. Most factories or corporations have chemical or corrosion-related material engineers who are better equipped to accurately specify instrument materials as they should be familiar with detailed information as well as experienced in their applications and usage.

This article is intended as a reference for users when they do not have access to such resources or other information sources. For any further questions, please consult customer service or a related professional expert to inquire about chemicals or conditions not covered in this article.

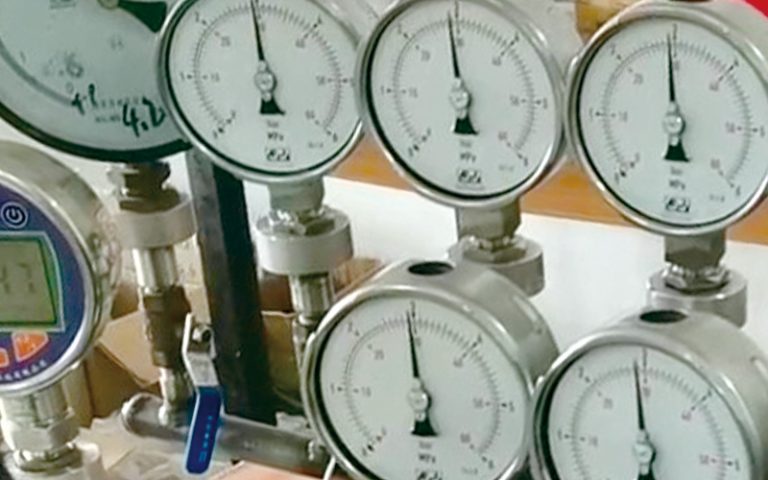

SJ Gauge: Pressure gauges or diaphragm pressure gauges, due to their measurement mechanics, have connectors that come into contact with the pressure source (medium). For fluids with corrosive properties, we often opt for pressure gauges with plastic connectors or diaphragms. The following list outlines the corrosion resistance of common plastic materials used in pressure gauges with different pressure sources (information is for reference only; actual conditions may vary, and on-site experience should be the primary consideration):

1. Stainless Steel 316/316L

Advantages:

- Ultra-low carbon 316L stainless steel minimizes harmful carbide precipitation caused by welding.

- Better corrosion resistance compared to 304 stainless steel.

- Excellent pitting corrosion resistance, good resistance to most chemicals in the paper, textile and photography industries.

- Good corrosion resistance in chloride environments, seawater and chemical environments (such as sulfur compounds, phosphoric acid and formic acid, as well as other organic acids).

- Good resistance to neutral and alkaline salts (including strong oxidizing salts).

Disadvantages:

- May corrode and crack in chloride solutions under internal/external stress.

- Susceptible to corrosion by non-oxidizing acids (most concentrations of sulfuric acid and hydrochloric acid).

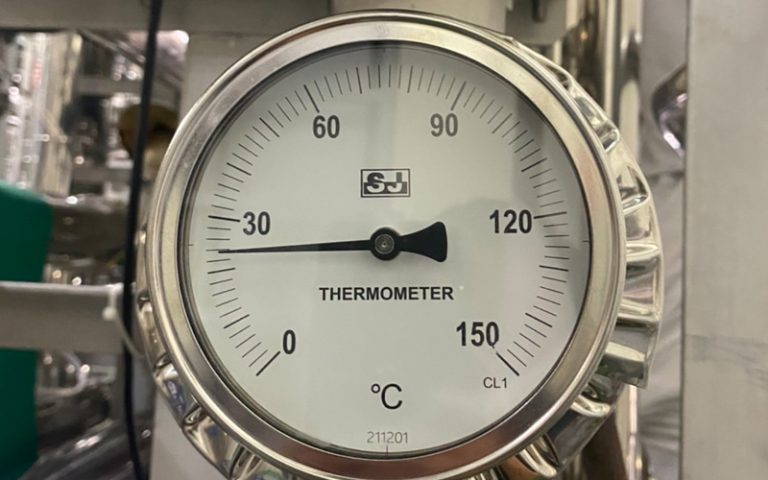

- Prone to corrosion and cracking in warm chloride environments, especially above 60°C (140°F).

2. Hastelloy C

Advantages:

- Excellent resistance to seawater corrosion.

- Outstanding corrosion resistance in seawater and chloride salt environments.

- Applicable to various inorganic and organic chemical processes.

- Resistant to moist chlorine and concentrated chlorine salt solutions.

- Good resistance to various non-oxidizing media (sulfuric acid, phosphoric acid and acetic acid).

- Good resistance to mixed oxidizing acids (nitric acid/sulfuric acid, chromium/sulfuric acid, sulfuric acid/copper sulfate, chromic acid and high manganese acid salts).

Disadvantages:

- Susceptible to hydrogen embrittlement.

- Hydrogen permeation can be mitigated with a gold coating.

3. Monel Alloy, Nickel-Copper Alloy Series (Commonly used in instrumentation – Monel 400)

Advantages:

- Resistant to various reducing media (fluorine, hydrofluoric acid, sulfuric acid, hydrogen fluoride and derivatives).

- Excellent resistance to seawater.

Disadvantages:

- Not recommended for use in caustic alkali evaporators and concentrators.

- Susceptible to hydrogen embrittlement.

- Hydrogen permeation can be mitigated with a gold coating.

4. Tantalum

Advantages:

- Excellent corrosion resistance to most acids (hydrochloric acid, nitric acid, phosphoric acid, sulfuric acid and acidic ferric chloride solutions), saltwater solutions and organic chemicals.

Disadvantages:

- Susceptible to corrosion by sulfur trioxide, hydrofluoric acid and strong alkaline solutions.

- Embrittlement may occur in the presence of hydrogen gas, high-temperature oxygen or nitrogen gas.

| O = This means the material is OK for the service. The uniform corrosion rate is less than 0.002 per year and there is no tendency for pitting or stress corrosion. This material may use a Bourdon tube, bellows, diaphragm, or lower housing. |

| L = Indicates the uniform corrosion rate is less than .020 inches per year and the material is suitable only for a diaphragm seal lower housing. It is NOT suitable for a Bourdon tube, bellows, or diaphragm. |

| X = This material is not recommended, insufficient information or complex restrictions cannot be addressed in this table. |

| Material | ||||||||

| Corrodent | Common Names & Formulas | Corrodent Temp. ºF MAX | Concentration % in H2O | 316, 316L SS | Monel | Nickel | Hastelloy C276 | Tantalum |

| ACETIC ACID | 200 | <40 | O | X | X | O | O | |

| ACETIC ANHYDRIDE | 200 | – | X | X | X | O | O | |

| ACETONE | 150 | – | O | O | O | O | O | |

| ACETYLENE, DRY | 200 | 100 | O | X | O | O | O | |

| ACROLEIN | 200 | 100 | L | L | L | L | O | |

| ALUMINUM CHLORIDE | AlCl3, Polyaluminum Chloride | 150 | – | X | X | X | O | X |

| ALUMINUM SULFATE | Alum. Al2(SO4)3 | 150 | <50 | L | X | X | O | O |

| AMMONIA ANHYDROUS | DOT Quality NH3 | 300 | 100 | O | X | X | L | X |

| AMMONIUM CHLORIDE | Sal Ammoniac NH4Cl | 200 | <40 | X | X | X | O | O |

| AMMONIUM HYDROXIDE | Ammonia Water NH3 in Water | 120 | <30 | O | X | X | L | X |

| AMMONIUM NITRATE | Norway Saltpeter NH4NO3 | 200 | <50 | O | X | X | L | O |

| AMMONIUM SULFATE | (NH4)2SO4 | 200 | <60 | L | X | L | L | O |

| AMYL ACETATE | 200 | <60 | O | X | X | O | O | |

| ANILINE | 250 | – | O | L | L | X | O | |

| BEER | 200 | >99 | O | X | X | X | X | |

| BENZENE | C6H6 | 200 | – | O | O | O | X | O |

| BENZIDINE | 200 | <50 | L | L | L | L | O | |

| BENZOIC ACID | 200 | <99 | L | L | L | O | O | |

| BLACK LIQUOR | 200 | <70 | X | X | X | X | X | |

| BLEACH | <5% NaOCl | 120 | <5 | X | X | X | O | O |

| BORIC ACID | H3BO4 | 150 | <25 | O | L | L | O | O |

| BROMINE, DRY (<57 PPM H2O) | Br | 140 | >99 | X | L | L | L | O |

| BROMOBENZENE | 200 | >99 | O | L | L | O | O | |

| BUTADIENE (BUTYLENE) | 200 | >99 | O | O | O | O | O | |

| BUTANE | 200 | – | O | O | O | O | O | |

| BUTYL ALCOHOL | C4H10 | 200 | – | O | O | O | O | O |

| BUTYRIC ACID | Butanol | 200 | <10 | L | X | X | O | O |

| CALCIUM BISULFATE | Ca(HSO3)2 | 250 | >90 | O | X | X | X | X |

| CALCIUM CHLORIDE | CaCl2 | 200 | <80 | X | X | X | O | O |

| CALCIUM HYDROXIDE | Slaked Lime Ca(OH)2 | 200 | <50 | L | X | X | O | O |

| CALCIUM HYPOCHLORITE | Ca(OCl)2 | 75< | <10 | X | X | X | L | O |

| CARBON DIOXIDE, WET | CO2 | 150 | >50 ppm | O | O | X | O | O |

| CARBON MONOXIDE | CO | 200 | >99 | O | O | X | O | O |

| CHLORINATED WATER (<10ppm Chlorine) | 70 | <10 ppm | O | O | X | O | O | |

| CHLORINATED WATER (To Saturation) | 120 | – | X | X | X | O | O | |

| CHLORINE, DRY (<50PPM H2O) | Cl2 | 200 | >99 | X | X | L | L | O |

| CHLORINE, MOIST | 160 | >90 | X | X | X | L | O | |

| CHLOROACETIC ACID | 150 | <30 | X | L | X | L | O | |

| CHLOROFORM, DRY | Trichloromethane CHCl3 | 100 | >99 | O | O | O | X | O |

| CHROMIC ACID | Chromium Trioxide H2CrO4″ | 200 | <30 | X | X | X | X | O |

| CITRIC ACID | 200 | >10 <50 | O | L | L | O | O | |

| COPPER NITRATE | Cupric Nitrate Cu(NO3)2 | 200 | <10 | O | X | X | X | O |

| COPPER SULFATE | Cupric Sulfate CuSO4 | 200 | <30 | L | X | X | O | O |

| CREOSOTE | Coal-Tar | 200 | – | L | L | L | O | O |

| CRESOL | 200 | >99 | O | O | O | O | O | |

| CRUDE OIL – SOUR | <200 | <5 | X | O | X | O | O | |

| CRUDE OIL – SWEET, LOW SULFUR | 200 | – | O | O | O | O | O | |

| CUPRIC CHLORIDE | Copper Chloride | 200 | <40 | X | X | X | X | O |

| DIESEL FUEL | 140 | – | O | O | O | O | O | |

| DOWTHERM A | 300 | – | O | O | O | O | O | |

| ETHANOL | Ethyl Alcohol C2H5OH | 200 | – | O | O | O | O | O |

| ETHANOL AMINES | MEA, DEA, TEA | 120 | 100 | O | O | L | O | O |

| ETHYL ACETATE | <200 | – | O | O | O | O | O | |

| ETHYL CHLORIDE, DRY | Chloroethane | <200 | >99 | X | O | O | O | O |

| ETHYLENE | Ethene | 200 | – | O | O | X | O | O |

| ETHYLENE GLYCOL | Glycol | 200 | >40 | O | L | L | O | O |

| ETHYLENE OXIDE | ETO | 100 | >99 | O | O | O | X | O |

| FERRIC CHLORIDE | FeCl3 | 200 | <40 | X | X | X | X | O |

| FERRIC SULFATE | Fe2(SO4)3 | 150 | <10 | O | X | X | O | O |

| FERROUS CHLORIDE | FeCl2 | 200 | <30 | X | X | X | L | O |

| FERROUS SULFATE | FeSO4 | 200 | <50 | X | X | X | L | O |

| FLUORINE, GAS DRY No Air or O2 | F2 | 200 | >99 | X | O | O | X | X |

| FLUOROSILICIC ACID | Hydrofluosilicic Acid – H2SiF6 | 140 | <30 | X | X | X | X | X |

| FORMALDEHYDE | 200 | – | O | O | O | X | O | |

| FORMIC ACID | <150 | – | X | X | X | L | O | |

| FUEL OIL, LIGHT | Diesel, No. 2, Heating Oil | 140 | – | O | O | O | O | O |

| FUEL OIL, HEAVY | Bunker, Resid, No. 6, Heavy Gas Oil | 300 | – | L | X | X | O | O |

| FURFURAL | 200 | <10 | X | L | L | O | O | |

| GASOLINE *FLOWING-PHOS BRONZE | 200 | – | O | X | X | O | O | |

| GLUCOSE | 300 | – | O | O | O | O | O | |

| GLYCERIN | Glycerol | 200 | – | O | O | O | O | O |

| HEXANE, DRY | 200 | >99 | O | O | O | O | O | |

| HYDRAZINE | 100 | – | X | X | X | X | X | |

| HYDROBROMIC ACID | HBr | 140 | – | X | X | X | X | O |

| HYDROCHLORIC ACID | HCl, Muriatic Acid | 100 | <38 | X | X | X | X | O |

| HYDROFLUORIC ACID (NO AIR) | HF | 120 | <50 | X | X | X | X | X |

| HYDROFLUOSILIC ACID | Fluosilicic Acid | 140 | <30 | X | X | X | X | X |

| HYDROGEN | H2 | 200 | – | O | X | X | X | X |

| HYDROGEN PEROXIDE | H2O2 | 100 | <30 | O | X | X | X | O |

| HYDROGEN SULFIDE | H2S | 140 | – | X | X | X | O | O |

| KEROSENE | Kerosine | 200 | >99 | O | O | O | O | O |

| LACTIC ACID | <100 | <70 | O | X | X | L | O | |

| MAGNESIUM CHLORIDE | MgCl2 | 200 | <40 | X | X | X | O | O |

| MAGNESIUM SULFATE | Epsom Salts MgSO4 | 200 | <40 | O | O | O | X | O |

| MERCURIC CHLORIDE | HgCl2 | 200 | <60 | X | X | X | X | O |

| MERCURY | Quicksilver Hg | 200 | >99 | O | X | O | O | X |

| METHANE DRY, NO H2S | CH4 | 200 | – | O | O | O | O | O |

| METHANOL | Wood Alcohol | 100 | >99 | O | O | O | O | O |

| METHYL ETHYL KETONE | M.E.K | 120 | >99 | O | X | X | X | X |

| MILK | – | – | O | X | X | O | X | |

| MORPHOLINE | 200 | >99 | O | O | O | O | X | |

| NAPHTHA | Benzin | 200 | >99 | O | O | O | O | O |

| NAPHTHALENE | Tar Camphor C10H8 | 150 | >99 | O | O | O | X | L |

| NATURAL GAS, DOT QUALITY *Cu alloy <100PSI | 150 | – | O | L | X | O | O | |

| NICKEL CHLORIDE | NiCl2 | 200 | <80 | X | X | X | O | O |

| NICKEL SULFATE | NiSO4 | 200 | – | O | X | X | X | X |

| NITRIC ACID | HNO3 | <100 | <95 | O | X | X | X | O |

| NITROUS OXIDE (DRY) | Laughing Gas N2O | <100 | >99 | L | X | X | L | O |

| N-METHYLPYRROLIDONE | NMP | 70 | >99 | L | X | O | O | X |

| OLEIC ACID | 200 | – | L | L | L | L | O | |

| OXALIC ACID | 140 | <50 | X | X | X | L | O | |

| OXYGEN GAS (“X6B”) | O2 | 120 | – | O | O | X | O | O |

| OZONE | O3 | 120 | <8 | O | X | X | X | X |

| PALMITIC ACID | 160 | >99 | O | X | X | O | X | |

| PHENOL | 120 | >90 | O | L | O | O | O | |

| PHOSPHORIC ACID | H3PO4 | 100 | <60 | O | X | X | O | O |

| PHTHALIC ANHYDRIDE | 200 | >99 | O | O | O | O | O | |

| PICRIC ACID | 200 | <10 | O | X | X | L | O | |

| POTASSIUM CHLORIDE | KCl | 150 | <30 | X | L | L | O | O |

| POTASSIUM HYDROXIDE | KOH | 160 | <50 | L | O | O | L | X |

| POTASSIUM NITRATE | Saltpeter KNO3 | 200 | <50 | L | L | L | L | O |

| POTASSIUM NITRITE | KNO2 | 200 | <50 | L | L | L | L | X |

| POTASSIUM PERMANGANATE M | KMnO4 | 140 | <30 | X | X | X | X | O |

| PROPANE | C3H8 | 200 | >99 | O | O | O | O | O |

| PROPYLENE | 200 | >99 | O | O | O | O | O | |

| ROSIN | 200 | – | O | O | O | O | ||

| SEA WATER *Monel not for Diaphragms | Ocean Water | 200 | – | X | O* | X | O | O |

| SEWAGE, RAW | 100 | – | L | L | X | O | O | |

| SILICONE OIL | PDMS | 140 | – | O | O | O | O | O |

| SILVER NITRATE (Acid free) | AgNO3 | 200 | <50 | L | X | X | X | O |

| SKYDROL | 200 | 100 | O | O | O | O | O | |

| SODIUM BICARBONATE | Baking Soda NaHCO3 | <200 | <20 | O | O | O | L | X |

| SODIUM BISULFATE | NaHSO4 | <200 | <30 | X | L | L | L | O |

| SODIUM BISULFITE | NaHSO3 | <150 | <40 | X | L | X | L | O |

| SODIUM CARBONATE | Soda Ash Na2CO3 | <200 | <40 | O | O | O | O | O |

| SODIUM CHLORIDE | Table Salt NaCl | <200 | <30 | X | O | L | O | O |

| SODIUM CHROMATE | Na2CrO4 | <200 | <60 | O | O | O | O | O |

| SODIUM CYANIDE | NaCN | <140 | – | O | X | X | X | O |

| SODIUM DICHROMATE | Na2Cr2O7 | <140 | <20 | O | X | X | X | X |

| SODIUM HYDROXIDE | Caustic Soda NaOH | <150 | <40 | O | O | O | O | X |

| SODIUM HYDROXIDE | Caustic Soda NaOH | <200 | <70 | X | O | O | L | X |

| SODIUM HYPOCHLORITE | NaOCl, Bleach | 120 | <40 | X | X | X | X | O |

| SODIUM NITRATE | Chile Saltpeter NaNO3 | <200 | – | O | X | O | X | O |

| SODIUM NITRITE | NaNO2 | <200 | <60 | O | O | O | O | O |

| SODIUM PERMANGANATE (pH >6, no chlorides) | NaMnO4 | <120 | <50 | O | X | O | O | O |

| SODIUM PEROXIDE | Na2O2 | <200 | <10 | O | L | L | L | X |

| SODIUM PHOSPHATE (TRIBASIC) | TSP Na3PO4 | <200 | <60 | O | O | O | O | O |

| SODIUM SILICATE | Water Glass | <200 | – | O | O | O | L | O |

| SODIUM SULFATE | Na2SO4 | <200 | <30 | O | L | L | L | O |

| SODIUM SULFIDE | Na2S | <200 | <30 | L | L | L | L | O |

| SODIUM SULFITE | Na2SO3 | <200 | <30 | O | X | X | O | O |

| SODIUM THIOSULFATE | Na2S2O3 | <200 | – | O | O | L | L | O |

| SOUR GAS / OIL | <200 | <5 | X | O | X | O | O | |

| STANNOUS CHLORIDE | Tin Dichloride SnCl2 | <200 | <50 | X | X | X | X | O |

| STEAM (WITH SIPHON) | <300 | – | O | O | O | O | O | |

| STEARIC ACID | <200 | – | O | X | O | O | O | |

| STODDARD SOLVENT | <150 | – | O | O | O | O | O | |

| SULFAMIC ACID | <150 | <95 | X | X | X | L | O | |

| SULFUR | S | 250 | >95 | X | X | X | O | O |

| SULFUR DIOXIDE, WET | SO2 | 140 | – | L | X | X | L | O |

| SULFUR HEXAFLUORIDE | SF6 | 120 | – | O | O | O | O | O |

| SULFUR TRIOXIDE, DRY | SO3 | 140 | >99 | L | X | L | O | X |

| SULFURIC ACID <60% | H2SO4 | 200 | <60 | X | X | X | X | O |

| SULFURIC ACID 80-98% | H2SO4 | 200 | <98 | X | X | X | X | O |

| TANNIC ACID | Tannin | <150 | – | O | O | X | X | O |

| TARTARIC ACID | <150 | <50 | O | O | X | X | O | |

| TOLUENE | Toluol | <200 | >99 | O | O | O | O | O |

| TRICHLOROACETIC ACID | <200 | <50 | X | L | X | O | X | |

| TRICHLOROETHANE 1,1,1, DRY | <150 | >98 | O | O | O | O | O | |

| TRICHLOROETHYLENE, DRY | <200 | >99 | O | O | O | O | O | |

| TURPENTINE | <200 | >98 | O | O | O | O | O | |

| UREA | Carbamide, DEF | <200 | <50 | O | X | X | X | X |

| VINYL CHLORIDE | <100 | >99 | O | O | X | O | O | |

This article provides limited information, and various applications come with different conditions that cannot be covered through the table in this article. The table is based on uncontaminated chemicals rather than complex mixtures. Additionally, many of the chemicals listed in this article are hazardous or toxic. In cases where information is insufficient, the risk is high or the chemical is extremely hazardous, material recommendations should not solely rely on the information provided in this article.

Users are responsible for conducting tests in their applications or consulting qualified and reliable material engineers, especially when dealing with chemicals that pose high risks or fall under the category of extremely hazardous substances.